What is Road Gully Spacing Thumb Rule? 6 Important Points

- By

- Pooja |

- January 20, 2021 |

- Civil Engineering, Drainage Engineering,

Table of Contents

Standard size Trapped Gully (or Flat Top Gully)

What is the Difference between Road Gully and Catchpit?

Road Gully Spacing plays a very important role while developing drainage design and modelling. Surface water flow width, longitudinal slopes and many other factors are considered to determine gully spacing, please read this blog for further detail:

What is Road Drainage?

Road Drainage is the normal or non-natural amputation of a surface's water and sub-surface water from a road surface. If the road surface water is not removed, it would severely weaken road pavement, particularly asphalt pavement. In case the surface water trickles down to the sub-base, the foundation of road pavement would lose its bearing strength and the road pavement may fail under heavy traffic conditions.

The absence of an adequate drainage system leads to having poor-quality road pavement such as potholes, uneven road surface, etc.

What is Road Gully?

Road Gully is a small pot placed along the road edge or kerb edge and covered from the top by placing gully grating which is made of a steel frame. The main purpose of Road Gully is to collate surface water of the road surface and then transmit it to the downstream career pipe and then ultimately discharge it to the existing drainage network or to an attenuation pond.

How does Road Gully Work?

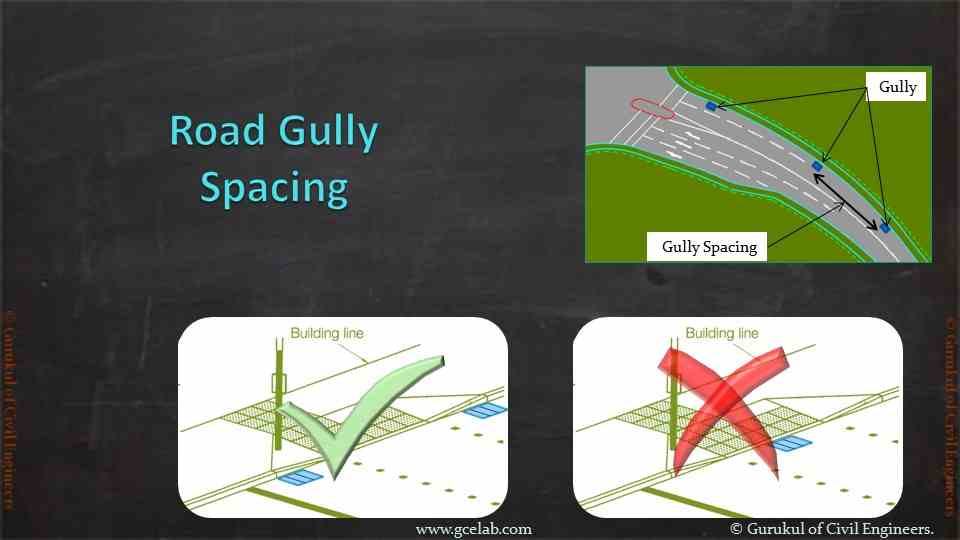

As mentioned above road gully collates surface water, so the principle of gully design works by placing several gullies at regular intervals and at low points along the road edges. Following are the thumb rules of gully spacing:

- Gully Spacing to be designed as per UK DMRB, HA-102.

- Surface Water Flow Width B = 0.75m.

- The surface area covered by one gully should not exceed 200 square meters area.

- The spacing between gullies should be in the range of 40 meters to 50 meters but in the case of sag curve or low points or lower side of the super-elevated road, it can be placed in the range of 25 meters to 30 meters.

The primary factor that affects the road gully spacing depends upon the surface water flow width. This means the higher the flow width, the greater the Gully spacing. It is recommended that the flow width doesn't spill over to the wheel track zone. Also, road edge treatment plays a very important role in collating surface water.

For example, if the road edge treatment is kerbed edge then water flow would be higher than the flush road edge with verge or permeable hard shoulders.

What is the Road Gully Types?

There are three types of Road Gullies commonly used for Road drainage systems.

Standard size Trapped Gully (or Flat Top Gully)

Standard-size Trapped Gully is the most common form of Gully. The gully pot comes with steel frame grating and flushes with the road surface.

Side Entry Gully

Side entry gully is preferred to minimise obstruction to on-road cyclists due to gully grating. Side Trapped gullies are generally flushed vertically with Kerb edges. The efficiency of side trap gullies is sometimes less than the standard flat-top gullies.

Gully Inset into Verges

Inset Gullies are preferred in highspeed motorways to minimise the obstruction to high-speed vehicles especially the hard shoulder or hard strip is very narrow.

What is the Difference between Road Gully and Catchpit?

Catchpit is like a pot having an outlet and inlet connection slightly above the floor level that collects debris and needs maintenance at infrequent interval. Catchpits are designed to be placed at steep slopes or non-highway locations. Also, they can be formed of various shapes, but Gullies are placed at road surface levels or footway surfaces or urban realm surfaces and collect surface water.

What is Road Gully Cleaning?

Road Gully Blockage is a common problem due to excessive debris collection or poor maintenance or bad weather condition or due to damage by heavy vehicles. If the blockages in the gully pot are not removed on time, it would lead to local flooding or leakage to sub-base or sub-grade levels or generate bad odours or may damage career pipe downstream.

Road Gully cleaning is carried out with advanced technologies along with vacuuming and high-pressure jetting through the water. CCTV surveys are carried out before performing high-pressure jetting. The survey records the status of the existing gully and pipe network.

It shows all the blockage within the network and the jetting help to clean out the blockages.

Motorway Gully Grating:

The Gully gratings are normally made from ductile iron and must comply with national design standards. In the UK it should be in accordance with DMRB HA104/09 for the Gully Grariting. Gully Gratings are placed flush with the road surface, along the kerbs and normally come with a hinge for the protection against theft.

Parallel straight bars are provided to stop the large items like stones, plastic cans, etc entering into the Gully Pot.

Super Gully:

Super Gully is an innovative Gully type for lost cost -low-frequency maintenance purposes. They are primarily used for the surface water control systems to remove surface water from the road surface rapidly.

The following are the key benefits of Super Gully:

- A rapid removal of surface water at low lying areas

- Low maintenance requirement

- Very useful for Car Park, Urban Street drainage solutions

- High Capacity Gullies

- Quick and Easy Installation

Smart Gully Adapter:

Smart Gully Adapter is developed to collate and remove oil, fine pollutant, grease, etc before it discharges out of the gully pot. These adapters are placed at the top level of the gully pot and with the help of a filter, it restricts pollutants to go further. The following are the key benefits of the Smart Gully Adapter:

- Innovative and low-cost solution.

- Collect various pollutants like oil, fine particles, grease, etc to enter and mix with the stormwater system.

Self-Cleansing Road Gully:

A self-cleansing road gully is a type of drainage system that is designed to remove debris and sediment from the roadway without the need for manual cleaning. This is typically achieved through the use of a grate or filter that allows water to pass through while trapping larger particles, or through the use of an inclined channel that allows sediment to flow away from the roadway. Some self-cleansing road gullies also incorporate mechanical cleaning devices such as brushes or jets to further aid in the removal of debris.

The main advantage of self-cleansing road gullies is that they can reduce the need for regular maintenance, making them more cost-effective and efficient than traditional drainage systems.

I hope this blog will help you understand the surface water collection through road gullies and thumb rules will help you to determine the road gully spacing.

Please feel free to like, share and comment.

Admin, gcelab.com Please see our Pillar Post to know why we founded gcelab.com.

Read More:

- Drainage Engineering Online Course: 4 Important Modules

- How to become a successful Drainage Engineer – 5 Key Points

- What is Drainage Flow Control Device? 7 Important Points

Pooja

Founder at gcelab.com, Pooja is an Entrepreneur unlocking human potential. Working in the Principles of Lean Start-up, Pooja believes in Transparency and User Happiness the most. Pooja’s background in teaching gives her a sophisticated grasp on even the most tedious aspect of course building. She is passionate about people who believe that good is not enough.